Case & Bullet Jacket Cups

Case Cups and Bullet Jacket Cups

In addition to our Rolled products and Coin Blank business, it was decided to start manufacturing Case Cups of various calibres, to meet the demand of Small Arm Ammunition manufacturers.

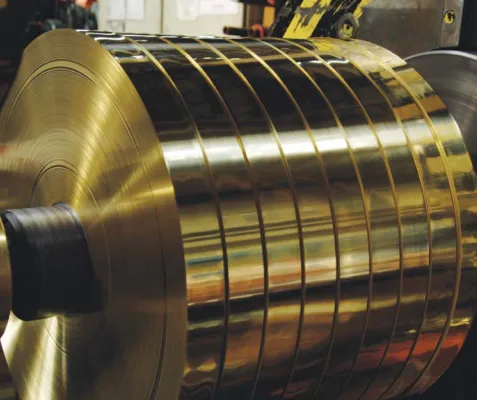

Our annual capacity for the production of Copper Alloy Strips is in excess of 10,000 MT and a large portion of our capacity is for supply of Strips and Coils for manufacturing Coin Blanks, catering to the Coinage Strip requirements of several Mints around the world. The remaining capacity will now be dedicated for Cups and Discs for the local and the International markets.

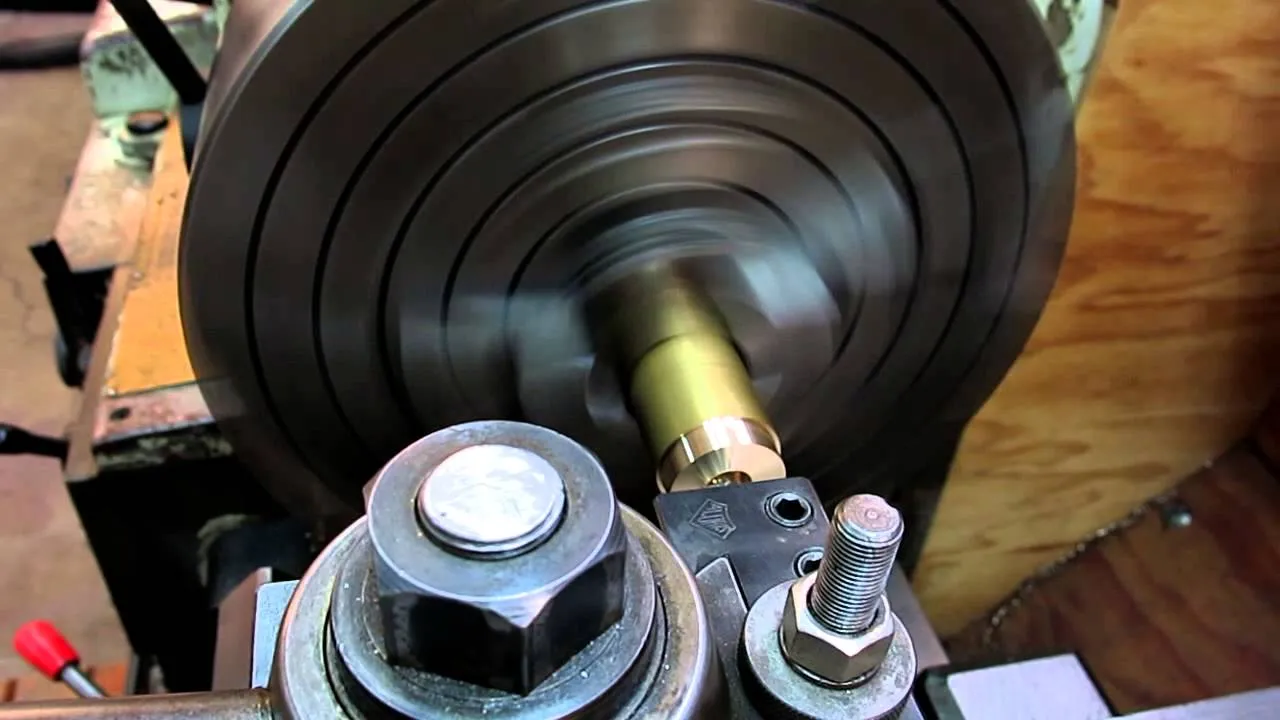

Various cartridge Case Cups and Bullet Jacket Cups can be manufactured in our facility on State-of the art Cupping presses. The process starts with manufacturing of Strips in our foundry and the desired thickness, width and alloys are produced on our effective and efficient downstream equipment’s and thereafter, sent to the Cupping presses. Heat treatment, washing, drying and rigorous quality inspection system ensures accuracy in size and quality, alongwith mechanical and surface properties for further processing.

Case Cups and Bullet Jacket Cups

As an extension to our rolled products and Coin International market. Blank business, it was decided to start manufacturing Case Cups of various calibres, to meet the demand of Small Arm Ammunition manufacturers.

Our annual capacity for the production of Copper Alloy Strips is in excess of 10,000 MT and a large portion of our capacity is for supply of Strips and Coils for manufacturing Coin Blanks, catering to the Coinage Strip requirements of several Mints around the world and also for automobile applications. The remaining capacity will now be dedicated for Cups and Discs for the local and the International market.

Various cartridge case cups and bullet jacket cups can be manufactured in our facility on State-of- the art Cupping presses. The process starts with manufacturing of Strips in our foundry and the desired thickness, width and alloys are produced on our effective and efficient downstream equipment’s and thereafter, sent to the Cupping presses. Heat treatment, washing, drying and rigorous quality inspection system ensures accuracy in size and quality, alongwith mechanical and surface properties.

Manufacturing Process

Case Cups & Bullet Jacket Cups

CUPS FOR CASES

| Small Arms Ammo Calibers |

|---|

| 7.62× 54MM |

| 7.62× 51MM |

| 7.62× 39MM |

| 5.56× 45MM |

| 9.00× 19MM |

| 12.70× 45MM |

| COMPYLING TTO NATO STANDARD |

CUPS FOR BULLETS

| Small Arms Ammo Calibers |

|---|

| 7.62× 54MM |

| 7.62× 51MM |

| 7.62× 39MM |

| 5.56× 45MM |

| 9.00× 19MM |

| 12.70× 45MM |

| COMPYLING TTO NATO STANDARD |

Brass Discs for Artillery Ammunition

| Brass Disc | Size |

|---|---|

| Brass Disc 25 mm PDR | 6.31 Inches +/- 0.0025 Inch DIA x 0.56 Inch +/- 0.005 Inch Thickness |

| Brass Disc 30 mm | 70 mm +/- 0.4 DIA x 15.24 - 0.25 mm Thickness for Case Cartridge |

| Brass Disc 37 mm | 79.76 mm - 0.38 mm DIA x 15.24 - 0.25 mm Thickness for Case Cartridge |

| Brass Disc 57 mm | 140 mm +/- 0.2 mm DIA x 22 mm +/- 0.1 mm Thickness for Case Cartridge |

| Brass Disc 105 mm | 180.975 mm +/- 0.254 mm DIA x 13.2 mm +/- 0.254 mm Thick |

| Brass Disc 105 mm | 240.66 mm - 0.4 mm x 20.3 - 0.25 mm |

| Brass Disc 122 mm | 200 mm +/- 0.1 mm DIA x 17 +/- 0.1 mm Thickness for Case |

| Brass Disc 125 mm | 215 mm +/- 0.1 mm DIA x 18 +/- 0.1 mm Thickness for Stub Base |

| Brass Disc 130 mm | 308 mm +/- 1.5 mm DIA x 24 +/- 0.1 mm Thickness |