Coin Blanks

Coin Blanks

The Most Popular Alloys

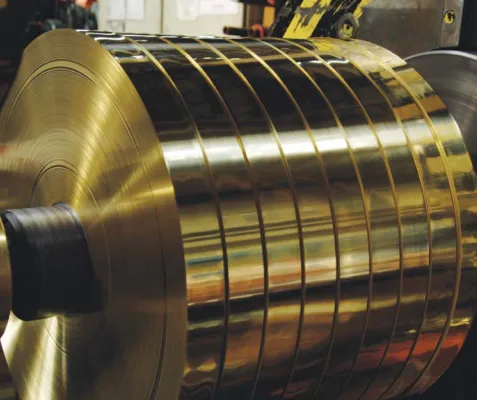

As an extension to the foundry division, a Moden, State-of-the-art and world-class coin blanks manufacturing facility was commissioned in India with equipment from leading suppliers equipments around the world. We are a leading manufacturer and supplier of Circulation Coin Blanks, regularly meeting the annual coinage requirement of Central Banks and Mints around the world.

We produce Mono-Matellic and Bi-Matellic ready to strike Coin Blanks, in all possible shapes sizes, and Alloys, with high quality and a degree of Technological and Metallurgical Sophistication, which has positioned us as the preferred source of supply among Central Bank of India, South East Asia, Africa, Europe, Eastern Europe, and South America etc.

Coin Blanks: The Foundation of Coinage

For every day use, modern coinage is based on metals such as Copper, Nickel, Zinc and Aluminium, with the preference given to a higher percentage of Copper. Despite enthusiasm for progress, Central Banks are often reluctant to make changes in the coins that are in circulation and changes if any, take place very slowly.

Central Banks consider various factors while choosing their coins and generally the seenerage and colour play an important role in the decision making process. There are three colours of coins that are widely used and these are Yellow, Reddish and White. The colours depend on the percentage of Copper, Zinc and Nickel in the coins.

Coinage materials around the world are generally categorized under four combinations and these are Cupro-Nickel, Nickel Silver, Brass, Bronze and Aluminium Bronze.

You would be pleased to know that 3C is regularly advising Central Banks on the alteration and renewals of existing series and has been instrumental in helping several Central Banks around the world in advising – designing – sampling and production of new issue of coins. 3C offers to Central Banks its technical assistance and advise to achieve an excellent end product and closely works with each one of them to overcome the difficulties encountered at any point of time. We are in a position to offer a comprehensive service to the issuing banks beginning with creative ideas for new coin values up to the delivery of coins free vault.

The following services are available ::

• Advice on design to complement existing series, alterations and renewals together with the introduction of new coins and coin series.

• Development of ideas on the form of new coin denominations including artistic and graphic design.

• Sampling of, and advice on, the suitability of coinage alloys.

• Integration of security features in coinage material and coin design.

• Supply of coins in collector quality in “proof like” or “proof” condition, in standard packing or luxury cases.

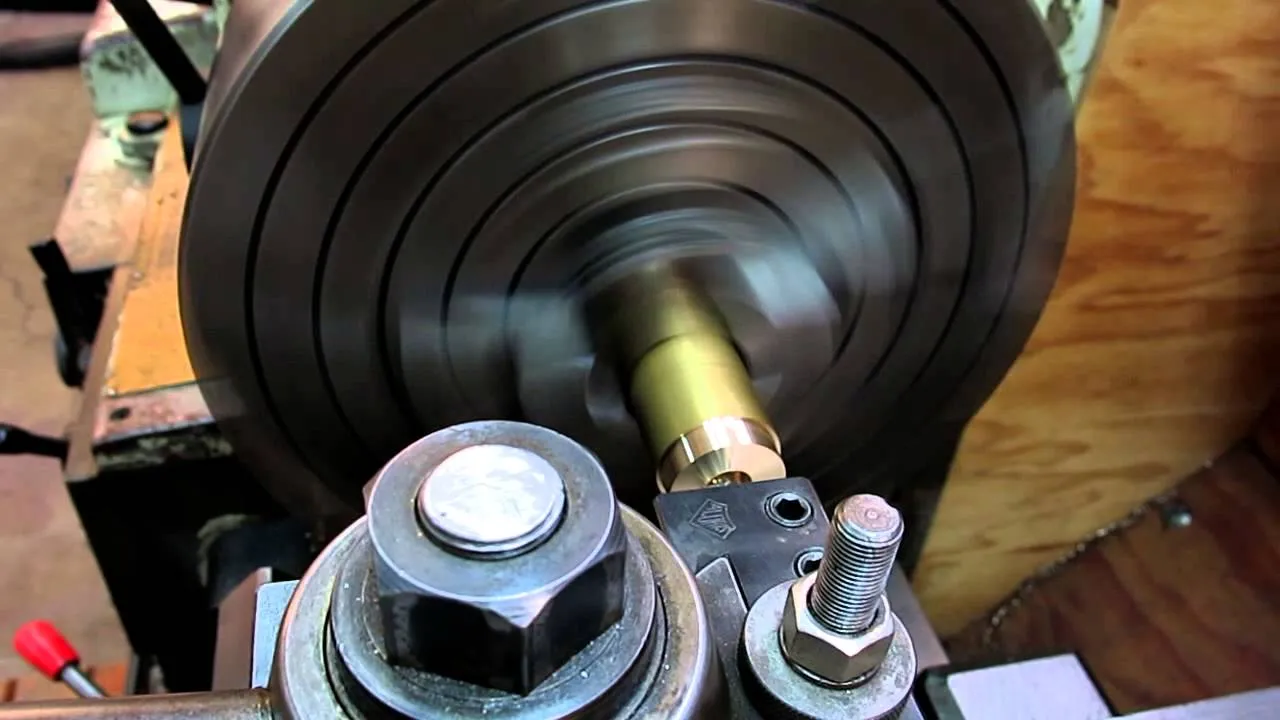

Manufacturing Process Coin Blanks

| 3C Coinage Material | |||||

|---|---|---|---|---|---|

| DIN Designation | Main Elements | Density (Kg/dm³) | Vickers Hardness | Properties | |

| Cupronickel 25 | CuNi 25 | Cu 75%, Ni 25% | 8.9 | 80 | White standard material |

| Cupronickel 16 | CuNi 16 | Cu 84%, Ni 16% | 8.9 | 75 | Yellowish-white |

| Cupronickel 10 | CuNi 10 | Cu 90%, Ni 10% | 8.9 | 75 | Reddish-white |

| Cupronickel 8 | CuNi 8 | Cu 92%, Ni 8% | 8.9 | 70 | Reddish |

| 3C Coinage Material | DIN Designation | Main Elements | Density (Kg/dm³) | Vickers Hardness | Properties |

|---|---|---|---|---|---|

| Brass 95/5 | CuZn5 | Cu 95%, Zn 5% | 8.9 | 65 | Red |

| Brass 90/10 | CuZn10 | Cu 90%, Zn 10% | 8.8 | 70 | Red |

| Brass 85/15 | CuZn15 | Cu 85%, Zn 15% | 8.8 | 70 | Red-golden |

| Brass 72/28 | CuZn28 | Cu 72%, Zn 28% | 8.6 | 75 | Yellow |

| Brass 70/30 | CuZn30 | Cu 70%, Zn 30% | 8.5 | 75 | Yellow |

| Brass 64/36 | CuZn36 | Cu 64%, Zn 36% | 8.4 | 85 | Yellow |

| Brass 60/40 | CuZn40 | Cu 60%, Zn 40% | 8.4 | 85 | Yellow |

| 3C Coinage Material | DIN Designation | Main Elements | Density (Kg/dm³) | Vickers Hardness | Properties |

|---|---|---|---|---|---|

| Nickel silver 25 | CuNi25Zn15 | Cu 60%, Ni 25%, Zn 15% | 8.8 | 85 | White |

| Nickel silver 18 | CuNi18Zn20 | Cu 62%, Ni 18%, Zn 20% | 8.7 | 85 | White |

| Nickel silver 15 | CuNi15Zn25 | Cu 60%, Ni 15%, Zn 25% | 8.7 | 85 | Still white |

| Nickel silver 12 | CuNi12Zn24 | Cu 64%, Ni 12%, Zn 24% | 8.7 | 85 | Yellowish-white |

| Nickel silver 9 | CuNi9Zn10 | Cu 81%, Ni 9%, Zn 10% | 8.75 | 70 | Golden-yellow |

| Nickel silver 6 | CuNi5.5Zn24.5 | Cu 70%, Ni 5.5%, Zn 24.5% | 8.7 | 85 | Light yellow |

| Nickel-brass | CuNi5Zn20 | Cu 75%, Zn 20%, Ni 5% | - | 80 | Golden-yellow |

| Nickel-brass | CuZn20Ni | Cu 79%, Zn 20%, Ni 1% | 8.7 | 70 | Golden-yellow |

| 3C Coinage Material | DIN Designation | Main Elements | Density (Kg/dm³) | Vickers Hardness | Properties |

|---|---|---|---|---|---|

| Aluminium-bronze 8 | CuAl8 | Cu 92%, Al 8% | 7.7 | 90 | Yellow |

| Aluminium-Nickel-Bronze 6 | CuAlNi2 | Cu 92%, Al 6%, Ni 2% | 8.1 | 85 | Yellow |

| Aluminium-Nickel-Bronze 5 | CuAl5Ni2 | Cu 93%, Al 5%, Ni 2% | 8.1 | 85 | Yellow |

| Aluminium-Nickel-Bronze 2 | CuAl2Ni6 | Cu 92%, Ni 6%, Al 2% | 8.6 | 85 | Reddish-brown |