Copper Alloy Strips

Copper & Copper Alloy Strips

3C produces strips in various alloys such as Brass, Nickel Silver, Cupro Nickel, Aluminium Bronze etc. Our Strips are produced on modern production equipments and an effective and efficient quality assurance system alongwith a highly qualified work force ensure that the strips meet extremely high quality standards.

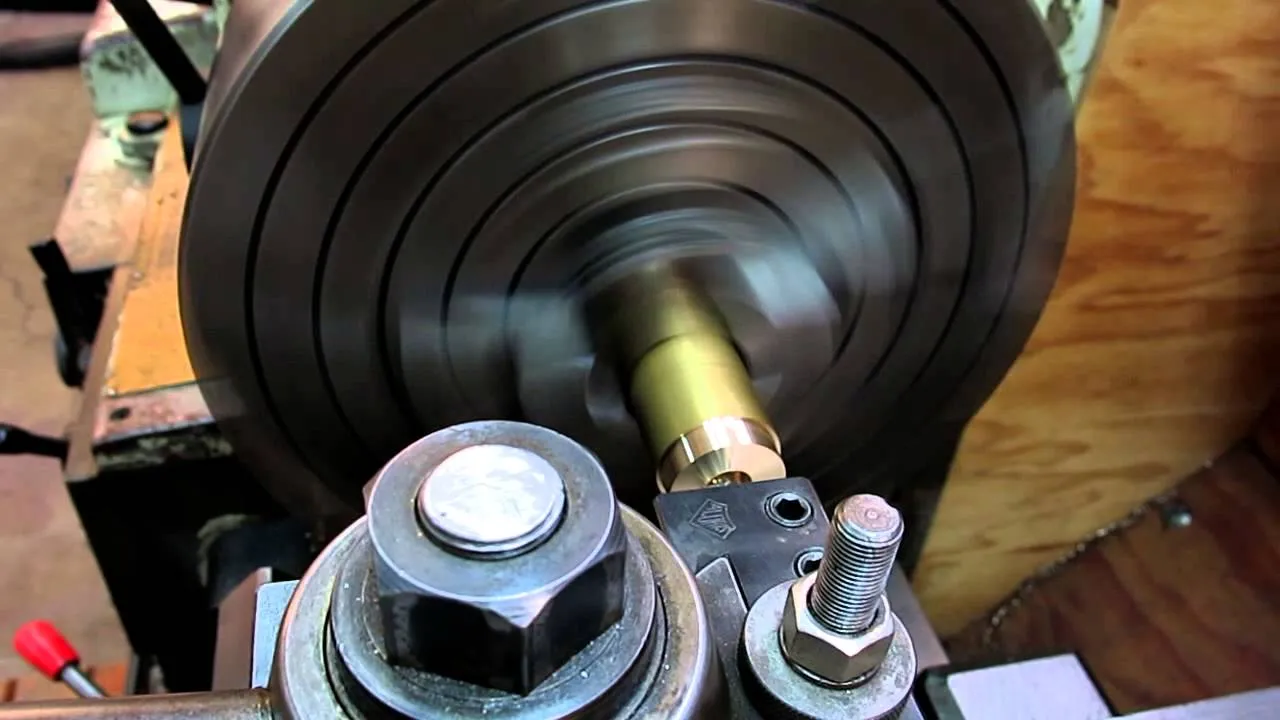

The quality of 3C products starts in the melting works followed by casting, double sided milling, intermediate rolling, annealing, pickling and superior final rolling. In Copper Alloy Strips : Only with the advancement of metallurgical technology, melting & casting alongwith integrated & sophisticated cold rolling & finishing technology. 3C is able to meet the customer demand with stringent product tolerances and services.

Today, our Strips used in a wide range of industries, especially for meeting the global demand for case cups, coinage, automobile industry etc. The variety of strips, the high quality and the degree of technological and metallurgical sophistication has positioned 3C as a leading supplier in India and abroad.

Manufacturing Process - Strips, Sheets & Coils

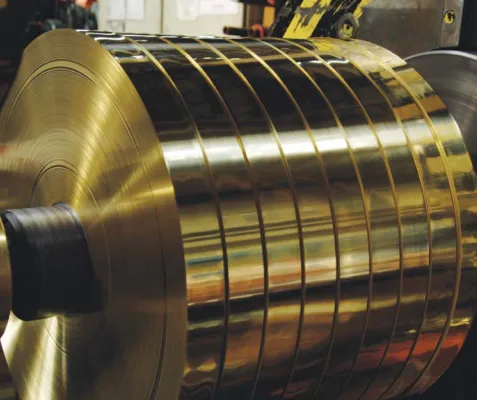

Brass Strips, Sheets & Coils

The brass strips form a wide product range of 3C. They are produced in high quality for universal application to satisfy the strictest requirements of customers. The raw material for the manufacturing is a cast strip, made by the modern continuous casting process. These strips have good cold workability that makes possible intensive and easy blanking. Annealed materials can be easily deep-drawn. Fields of application are Cartridge Case Cups, Bullet Jacket Cups, Coin Blanks, electronics, lighting techniques, metal decoration material industry, the vehicle industry, and the production of household items. Special hard grades are used as spring switch parts. The grades with homogeneous structures are used to manufacture components for the refrigerating industry. The strips can be easily polished.

After special heat treatment to control the grain size, the materials are suitable for multi-grade cold drawing of high level. Soft qualities can be delivered with pickled surface too. The excellent surface quality is guaranteed by the special technology (multi-step surface processing, bright annealing) developed by 3C. Good flatness and trueness to shape is characteristics of the material. For special request, tensile levelling is increasing the trueness to shape under 1 mm thickness.

| Chemical Composition-Alloy | ||||||||

|---|---|---|---|---|---|---|---|---|

| Alloy | EN No | Cu% | Zn% | Al% | Fe% | Ni% | Pb% | Sn% |

| CuZn10 | CW501L | 89,0-91,0 | Rest | 0,02 | 0,05 | 0,30 | 0,05 | 0,10 |

| CuZn15 | CW502L | 84,0-86,0 | Rest | 0,02 | 0,05 | 0,30 | 0,05 | 0,10 |

| CuZn28 | CW504L | 71,0-73,0 | Rest | 0,02 | 0,05 | 0,30 | 0,05 | 0,10 |

| CuZn30 | CW505L | 69,0-71,0 | Rest | 0,02 | 0,05 | 0,30 | 0,05 | 0,10 |

| CuZn33 | CW506L | 66,0-68,0 | Rest | 0,02 | 0,05 | 0,30 | 0,05 | 0,10 |

| CuZn36 | CW507L | 63,5-65,5 | Rest | 0,02 | 0,05 | 0,30 | 0,10 | 0,10 |

| CuZn37 | CW508L | 62,0-64,0 | Rest | 0,05 | 0,10 | 0,30 | 0,10 | 0,10 |

| Physical Properties | ||||||

|---|---|---|---|---|---|---|

| Alloy | EN No | Density g/cm³ | Electrical Conductivity | Thermal Conductivity | Modulus of Elasticity | |

| MS/m | % IACS | W/mK | kN/m² | |||

| CuZn10 | CW501L | 8,80 | 25,7 | 44 | 188 | 124 |

| CuZn15 | CW502L | 8,75 | 21,1 | 40 | 161 | 122 |

| CuZn28 | CW504L | 8,57 | 16,9 | 29 | 124 | 116 |

| CuZn30 | CW505L | 8,53 | 16,4 | 28 | 121 | 114 |

| CuZn33 | CW506L | 8,47 | 15,5 | 27 | 116 | 112 |

| CuZn36 | CW507L | 8,45 | 15,8 | 27 | 116 | 110 |

| CuZn37 | CW508L | 8,44 | 16,0 | 28 | 116 | 110 |

| Mechanical Properties | ||||||||

|---|---|---|---|---|---|---|---|---|

| Alloy | Hardness | Hardness Tensile Strength N/mm² | Yield Strength N/mm² | Elongation % | Hardness HV | |||

| Min. | Max. | Below 2.5mm Min. | Over 2.5mm Min. | Min. | Max. | |||

| CuZn10 | H050 | 240 | 290 | max.140 | 36 | 45 | 50 | 80 |

| H080 | 280 | 360 | min.200 | 13 | 20 | 80 | 110 | |

| H110 | 350 | - | min.290 | 4 | 8 | 110 | - | |

| CuZn15 | H055 | 260 | 310 | max.170 | 36 | 45 | 55 | 85 |

| H085 | 300 | 370 | min.150 | 16 | 25 | 85 | 115 | |

| H105 | 350 | 420 | min.250 | 4 | 12 | 105 | 135 | |

| H125 | 410 | - | min.360 | - | - | 125 | - | |

| CuZn28 CuZn30 | H055 | 270 | 350 | max.160 | 40 | 50 | 55 | 90 |

| H095 | 350 | 430 | min.170 | 21 | 33 | 95 | 125 | |

| H125 | 410 | 490 | min.260 | 9 | 15 | 120 | 155 | |

| H150 | 480 | - | min.430 | - | - | 150 | - | |

| CuZn33 | H055 | 280 | 380 | max.170 | 40 | 50 | 55 | 90 |

| H095 | 350 | 430 | min.170 | 23 | 31 | 95 | 125 | |

| H125 | 420 | 500 | min.300 | 6 | 13 | 125 | 155 | |

| H150 | 500 | - | min.450 | - | - | 155 | - | |

| CuZn36 CuZn37 | H055 | 300 | 370 | max.180 | 38 | 48 | 55 | 90 |

| H095 | 350 | 440 | min.170 | 19 | 28 | 95 | 125 | |

| H125 | 410 | 490 | min.300 | 8 | 12 | 120 | 155 | |

| H150 | 480 | 560 | min.430 | 3 | - | 180 | 180 | |

| H170 | 550 | - | min.500 | - | - | 170 | - | |

| General Properties of Brass Strip | Applications of Brass Strip |

|---|---|

| Good Electrical Conductivity | Cartridge Case cups, Bullet jacket cups |

| Good Thermal Conductivity | Coin Blanks, Electrical Components, Springs |

| Perfect Strength | Switches, Contacts, Relays, Connector |

| Good Corrosion Resistance | Jewellery Production |

| Good for Soldering | Textile |

| Good for Brazing | Automotive Industry, Radiator & Heat Exchanger |

| Suitable for Plating Other Metals | Decoration |

| Perfect Machinability | Architectural |

| Wear Resistance | Sanitary Ware |

| Good Ductility and Cold Forming | Connecting Parts |

| Good Extrudability | Key Production |

Copper

Strips, Sheets & Coils

Our Company uses LME Grade A Copper Cathodes for existing ETP, DHP, TBC and OFXLP. Strips produced in our premises have a smooth and polished surface with clean edges. Our equipments are all imported and state of the art in high quality. Only with the advancement of metallurgical technology, melting and casting alongwith integrated and sophisticated cold rolling and furnishing technology. 3C is able to meet the customer demand with stringent product tolerances and services.

| Alloy Name | Cu-ETP | Cu-DHP | Cu-TBC |

|---|---|---|---|

| Trade Name | Electrolytic Tough Pitch Copper | Deoxidized, High Residual Phosphorus Copper | Tin Bearing Copper |

| Standard Conformance | IS 191/ 14811/ 1897 | IS 191/ 14811/ 1897 | IS 3331 |

| ASTM | C11000 | C12200 | C14410 |

| BS 2870 | C101 | C106 | - |

| EN 1652 | CW004A | CW024A | - |

| JIS | C1100 | C1220 | - |

| Chemical Composition | Cu-ETP | Cu-DHP | Cu-TBC |

|---|---|---|---|

| Copper (Cu%) | 99.90 Min | 99.90 Min | 99.50 Min |

| Tin (Sn%) | - | - | 0.07 - 0.20 |

| Phosphorous (P%) | - | 0.015 - 0.040 | 0.015 - 0.045 |

| Other Impurities (%) | - | - | - |

| Alloy Name | Trade Name | Temper | Hardness HV | Tensile Strength N/mm² (Min) | Elongation % Min |

|---|---|---|---|---|---|

| Cu-ETP Copper/ Tape | Electrolytic Tough Pitch Copper | Annealed (O) | 55 Max | 195 Min | 35 |

| Quarter Hard (HA) | 55-75 | 215 Min | 25 | ||

| Half Hard (HB) | 75-90 | 250 Min | 15 | ||

| Hard (H) | 90 Min | 274 Min | - | ||

| Extra Hard (HE) | 110 Min | 340 Min | - | ||

| Cu-DHP | Deoxidized, High Residual Phosphorus Copper | Annealed (O) | 55 Max | 195 Min | 35 |

| Quarter Hard (HA) | 55-75 | 215 Min | 25 | ||

| Half Hard (HB) | 75-90 | 250 Min | 15 | ||

| Hard (H) | 90 Min | 274 Min | - | ||

| Extra Hard (HE) | 110 Min | 340 Min | - | ||

| Cu-TBC | Tin Bearing Copper | Annealed (O) | 60 Max | - | - |

| Quarter Hard (HA) | 60-80 | - | - | ||

| Half Hard (HB) | 80-100 | - | - | ||

| Hard (H) | 105-125 | - | - | ||

| Extra Hard (HE) | 125-145 | - | - |

| Alloy | For Strips and Foils | For Sheets | |||

|---|---|---|---|---|---|

| Thickness Range (Min - Max) mm | Coil ID (Min - Max) mm | Coil Density (Max coil weight) | Thickness Range (Min - Max) mm | Length (Max) mm | |

| Copper (XLPE, ETP, DHP, TBC) | 0.030 - 0.3 | 100 - 300 | 02-Mar | - | - |

| 0.031 - 0.80 | 100 - 300 | 02-Mar | 0.30 - 1 | 1500 | |

| 0.81 - 3.00 | 300 - 500 | 02-Mar | 1 - 3.00 | 4000 | |

| Alloy | For Strips and Foils | For Sheets | |||

|---|---|---|---|---|---|

| Thickness Range (Min - Max) mm | Coil ID (Min - Max) mm | Coil Density (Max coil weight) | Width Range (Min - Max) mm | Length (Max) mm | |

| Copper (XLPE, ETP, DHP, TBC) | 10 - 350 | 100 - 300 | 02-Mar | - | - |

| 10 - 450 | 100 - 300 | 02-Mar | 450 Max | 1500 | |

| 20 - 400 | 300 - 500 | 02-Mar | 450 Max | 4000 | |

Nickel - Silver

Strips, Sheets & Coils

Because of their high strength, corrosion resistance and other excellent mechanical properties, the nickel silver strips are suitable for a wide range of applications. They are mainly used in electrotechnics, electronics, telecommunication and light techniques, food industry and instrument production. Each hard grade of them is excellently suitable to produce springs. They are used for coin production and as household items. The Nickel-Silver Strips can be easily and intensively cold worked, blanked and deep drawn. These strips are produced on up-to-date continuous casting equipment and high precision rolling mills.

| Alloy | Nominal Strength | Tensile Strength (N/mm²) | Elongation A10 min% | Brinell | Vickers | ||

|---|---|---|---|---|---|---|---|

| min | max | min | max | ||||

| CuNi12Zn24 | F-36 | 360-430 | 40 | 75 | 105 | 80 | 110 |

| F-43 | 430-510 | 13 | 100 | 140 | 120 | 150 | |

| F-51 | 510-590 | 5 | 140 | 170 | 150 | 180 | |

| F-56 | 590-650 | - | 160 | 180 | 170 | 200 | |

| F-65 | > 650 | - | 190 | - | 200 | - | |

| CuNi18Zn20 | F-38 | 380-450 | 32 | 80 | 110 | 85 | 115 |

| F-45 | 450-520 | 15 | 110 | 150 | 115 | 150 | |

| F-52 | 520-610 | 10 | 150 | 180 | 160 | 190 | |

| F-58 | 610-680 | - | 170 | 190 | 180 | 200 | |

| F-68 | > 680 | - | 200 | - | 210 | - | |

| CuNi18Zn27 | F-39 | 390-470 | 35 | 85 | 115 | 90 | 120 |

| F-47 | 470-540 | 15 | 115 | 160 | 120 | 170 | |

| F-54 | 540-620 | 10 | 160 | 190 | 170 | 200 | |

| F-60 | 620-700 | - | 180 | 210 | 190 | 220 | |

| F-70 | > 700 | - | 210 | - | 220 | - | |

| Alloy | Cu % | Ni % | Zn % | These are the maximum % in the chemical composition | ||||

|---|---|---|---|---|---|---|---|---|

| Mn% | Fe% | Sn% | Pb% | Sum. % # | ||||

| CuNi12Zn24 | 63.0 - 66.0 | 11 - 13 | REST | 0.50 | 0.30 | 0.03 | 0.03 | 0.10 |

| CuNi18Zn20 | 60.0 - 63.0 | 17 - 19 | REST | 0.50 | 0.30 | 0.03 | 0.03 | 0.10 |

| CuNi18Zn27 | 53.5 - 56.5 | 17 - 19 | REST | 0.50 | 0.30 | 0.03 | 0.03 | 0.10 |

| THICKNESS | TOLERANCE | ||

|---|---|---|---|

| mm | inch | mm | inch |

| 0.10 - 0.20 | 0.003935 - 0.007870 | +/- 0.010 | +/- 0.000393 |

| 0.21 - 0.30 | 0.008263 - 0.011805 | +/- 0.015 | +/- 0.000590 |

| 0.31 - 0.50 | 0.012198 - 0.019675 | +/- 0.020 | +/- 0.000787 |

| 0.51 - 0.80 | 0.020068 - 0.031480 | +/- 0.025 | +/- 0.000983 |

| 0.81 - 1.40 | 0.031873 - 0.055090 | +/- 0.030 | +/- 0.001180 |

| 1.41 - 2.00 | 0.055483 - 0.078700 | +/- 0.040 | +/- 0.001574 |

| 2.01 - 2.80 | 0.079093 - 0.110180 | +/- 0.050 | +/- 0.001967 |

| 2.81 - 3.00 | 0.110573 - 0.118050 | +/- 0.060 | +/- 0.002361 |

| WIDTH TOLERANCE (mm) | ||||

|---|---|---|---|---|

| Thickness (mm) | 0 - 100 | 100 - 200 | 200 - 350 | 350 - 500 |

| 0.10 - 1.00 | +/- 0.2 | +/- 0.4 | +/- 0.6 | +/- 1.0 |

| 1.01 - 2.00 | +/- 0.3 | +/- 0.5 | +/- 1.0 | +/- 1.2 |

| 2.01 - 2.50 | +/- 0.5 | +/- 0.7 | +/- 1.2 | +/- 1.5 |

| 2.51 - 3.00 | +/- 1.0 | +/- 1.2 | +/- 1.5 | +/- 2.0 |

| General Properties of Nickel Silver Strip | Applications of Nickel Silver Strip |

|---|---|

| Good Electrical Conductivity | Electrical Components |

| Good Thermal Conductivity | Jewellery Production |

| Good Cold Forming | Textile |

| Perfect Strength | Decoration |

| Perfect for Soldering | Coin Production |

| Perfect for Brazing | Connecting Parts |

| Perfect Machinability | Key Production |

Phosphorus Bronze

Strips, Sheets & Coils

Phosphor Bronzes find wide applications in the electrical and electronic industry. They have excellent cold workability and relatively high strength and adequate electrical conductivity. Their fatigue strengths are high enough to make them suitable for application where repetitive actions stress the components, as in fasteners, electrical connectors, springs, electrical switches and similar products. Phosphor Bronzes are known to have the highest electrical conductivity, highest strength and best retention of strength at the component operating temperature, and ease and consistency of formability to components.

| Alloy | UNS No. | Copper Cu% | Tin Sn% | Phosphorous P% | Iron Fe% (max) | Lead Pb% (max) | Zinc Zn% (max) |

|---|---|---|---|---|---|---|---|

| CuSn4 | C-51100 | Remainder | 3.5-4.9 | 0.03-0.35 | 0.10 | 0.05 | 0.30 |

| CuSn5 | C-51000 | Remainder | 4.2-5.8 | 0.03-0.35 | 0.10 | 0.05 | 0.30 |

| CuSn6 | C-51900 | Remainder | 5.0-7.0 | 0.03-0.35 | 0.10 | 0.05 | 0.20 |

| CuSn8 | C-52100 | Remainder | 7.0-9.0 | 0.03-0.35 | 0.10 | 0.05 | 0.20 |

| ALLOY | Temper | Tensile Strength (N/mm²) | Elongation A10 min% | Vickers Hardness |

|---|---|---|---|---|

| CuSn4 | Soft | 300-410 | 38 | 80-100 |

| ½Hard | 410-520 | 12 | 150-180 | |

| Hard | 490-600 | 7 | 180-200 | |

| Spring Hard | 600-685 | - | 200-220 | |

| CuSn5 | Soft | 304-373 | 40 | 80-100 |

| ½Hard | 471-569 | 15 | 160-190 | |

| Hard | 569-618 | 7 | 190-210 | |

| Spring Hard | 618 Min. | - | 210-225 | |

| CuSn6 | Soft | 314-392 | 42 | 85-110 |

| ½Hard | 410-500 | 20 | 170-200 | |

| Hard | 588-650 | 8 | 200-225 | |

| Spring Hard | 650 Min. | - | 225 Min | |

| CuSn8 | Soft | 365-460 | 55 | 90-120 |

| ½Hard | 540-630 | 20 | 170-190 | |

| Hard | 590-690 | 15 | 190-220 | |

| Spring Hard | 660 Min. | - | 230 Min |

| THICKNESS | TOLERANCE | ||

|---|---|---|---|

| mm | inch | mm | inch |

| 0.10 - 0.20 | 0.003935 - 0.007870 | +/- 0.010 | +/- 0.000393 |

| 0.21 - 0.30 | 0.008263 - 0.011805 | +/- 0.015 | +/- 0.000590 |

| 0.31 - 0.50 | 0.012198 - 0.019675 | +/- 0.020 | +/- 0.000787 |

| 0.51 - 0.80 | 0.020068 - 0.031480 | +/- 0.025 | +/- 0.000983 |

| 0.81 - 1.40 | 0.031873 - 0.055090 | +/- 0.030 | +/- 0.001180 |

| 1.41 - 2.00 | 0.055483 - 0.078700 | +/- 0.040 | +/- 0.001574 |

| 2.01 - 2.80 | 0.079093 - 0.110180 | +/- 0.050 | +/- 0.001967 |

| 2.81 - 3.00 | 0.110573 - 0.118050 | +/- 0.060 | +/- 0.002361 |

| WIDTH TOLERANCE (mm) | ||||

|---|---|---|---|---|

| Thickness (mm) | 0 - 100 | 100 - 200 | 200 - 350 | 350 - 500 |

| 0.10 - 1.00 | +/- 0.2 | +/- 0.4 | +/- 0.6 | +/- 1.0 |

| 1.01 - 2.00 | +/- 0.3 | +/- 0.5 | +/- 1.0 | +/- 1.2 |

| 2.01 - 2.50 | +/- 0.5 | +/- 0.7 | +/- 1.2 | +/- 1.5 |

| 2.51 - 3.00 | +/- 1.0 | +/- 1.2 | +/- 1.5 | +/- 2.0 |

| General Properties of Phosphorus Bronze Strip | Applications of Phosphorus Bronze Strip |

|---|---|

| Good Electrical Conductivity | Telecommunication industry |

| Good Thermal Conductivity | Clutch Discs, Terminals, Valve Diaphragm and parts requiring springing characteristics |

| Good Cold Forming | Connectors, Electronic industry |

| Perfect Strength | Fuse Clips, Lock Washers |

| Perfect for Soldering | Switch Parts |

| Perfect for Brazing | Perforated Sheets, Springs, Surgical & Dental Equipment |

| Perfect Machinability | - |

Aluminium Bronze

The Aluminium Bronze strips are a speciality product of 3C. We are the only copper alloy strip manufacturer in India that has the technical capability to produce and supply different grades of Aluminium Bronze strips for various applications. 3C is produces these strips as per the electrical conductivity require by the end product. We manufactures these strips on its modern & state-of-the-art equipment and the strips are supplied in ready to use form.

| Alloy | Copper Cu % | Nickel Ni % | Aluminium Al % | Iron Fe % Max | Manganese Mn % Max | Lead Pb % Max | Others | Hardness VPN |

|---|---|---|---|---|---|---|---|---|

| CuAl8 | 91-93 | - | 7.5-8.5 | 0.03 | 0.05 | 0.003 | 0.1 | As per requirement |

| CuAl6Ni2 | 91-93 | 1.5-2.5 | 5-7 | 0.03 | 0.05 | 0.003 | 0.1 | As per requirement |

| CuAl5Ni2 | 91-93 | 1.5-2.5 | 4.5-5.5 | 0.03 | 0.05 | 0.003 | 0.1 | As per requirement |

| CuNi6Al2 | 91-93 | 5.5-6.5 | 1.5-2.5 | 0.03 | 0.05 | 0.003 | 0.1 | As per requirement |

| CuNi5Al5Fe | 88-90 | 4.5-5.5 | 4.5-5.5 | 1.00 | 0.05 | 0.003 | 0.1 | As per requirement |

| ALLOY | Temper | Tensile Strength (N/mm²) | Elongation A10 min% | Vickers Hardness |

|---|---|---|---|---|

| CuSn4 | Soft | 300-410 | 38 | 80-100 |

| ½Hard | 410-520 | 12 | 150-180 | |

| Hard | 490-600 | 7 | 180-200 | |

| Spring Hard | 600-685 | - | 200-220 | |

| CuSn5 | Soft | 304-373 | 40 | 80-100 |

| ½Hard | 471-569 | 15 | 160-190 | |

| Hard | 569-618 | 7 | 190-210 | |

| Spring Hard | 618 Min. | - | 210-225 | |

| CuSn6 | Soft | 314-392 | 42 | 85-110 |

| ½Hard | 410-500 | 20 | 170-200 | |

| Hard | 588-650 | 8 | 200-225 | |

| Spring Hard | 650 Min. | - | 225 Min | |

| CuSn8 | Soft | 365-460 | 55 | 90-120 |

| ½Hard | 540-630 | 20 | 170-190 | |

| Hard | 590-690 | 15 | 190-220 | |

| Spring Hard | 660 Min. | - | 230 Min |

| THICKNESS | TOLERANCE | ||

|---|---|---|---|

| mm | inch | mm | inch |

| 0.10 - 0.20 | 0.003935 - 0.007870 | +/- 0.010 | +/- 0.000393 |

| 0.21 - 0.30 | 0.008263 - 0.011805 | +/- 0.015 | +/- 0.000590 |

| 0.31 - 0.50 | 0.012198 - 0.019675 | +/- 0.020 | +/- 0.000787 |

| 0.51 - 0.80 | 0.020068 - 0.031480 | +/- 0.025 | +/- 0.000983 |

| 0.81 - 1.40 | 0.031873 - 0.055090 | +/- 0.030 | +/- 0.001180 |

| 1.41 - 2.00 | 0.055483 - 0.078700 | +/- 0.040 | +/- 0.001574 |

| 2.01 - 2.80 | 0.079093 - 0.110180 | +/- 0.050 | +/- 0.001967 |

| 2.81 - 3.00 | 0.110573 - 0.118050 | +/- 0.060 | +/- 0.002361 |

| WIDTH TOLERANCE (mm) | ||||

|---|---|---|---|---|

| Thickness (mm) | 0 - 100 | 100 - 200 | 200 - 350 | 350 - 500 |

| 0.10 - 1.00 | +/- 0.2 | +/- 0.4 | +/- 0.6 | +/- 1.0 |

| 1.01 - 2.00 | +/- 0.3 | +/- 0.5 | +/- 1.0 | +/- 1.2 |

| 2.01 - 2.50 | +/- 0.5 | +/- 0.7 | +/- 1.2 | +/- 1.5 |

| 2.51 - 3.00 | +/- 1.0 | +/- 1.2 | +/- 1.5 | +/- 2.0 |

| General Properties of Aluminium Bronze Strip | Applications of Aluminium Bronze Strip |

|---|---|

| Corrosion Resistance | Coin Production |

| Temperature Resistance | Weapon handling system |

| Perfect Strength | Fasteners |

| Good Machinability | Pumps Gears & Shafts |